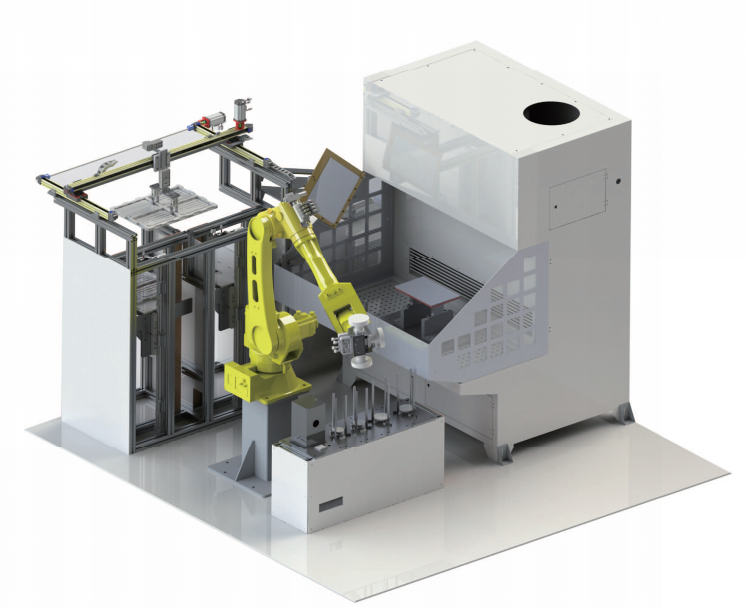

Short Description:The Robot Grinding Solution is a fully integrated, enclosed workstation designed for high-efficiency industrial finishing. Featuring a high-performance robot with a 1721mm working radius and integrated dust removal capabilities, this turnkey cell provides a safe, clean, and automated environment for grinding, deburring, and polishing metal components.

Key Attributes Table:

Product Model | Grinding Workstation | Max Power | 6.3 KW |

Working Radius | 1721 mm | Power Source | AC 220V 50HZ |

Repeatability | ±0.1 mm | Cabinet Size | 1300*650*1500 mm |

Cycle Time | ~3 min / interval | Dust Removal | Integrated System |

Product Details

Innovative Design Features

· All-in-One Workstation: This is not just a robot arm; it is a complete production cell. The system integrates the 6-axis robot, grinding spindles, electrical cabinets, and loading stations into a unified framework, minimizing installation time and floor space requirements.

· Environmental Control: Engineered for clean manufacturing, the workstation includes dust removal equipment selected specifically based on your actual working conditions. This effectively captures metal dust and debris, protecting both the machinery and the workshop environment.

· Optimized Workspace: With a maximum working radius of 1721mm and a robust drive system, the robot can handle multiple processing steps within the cell without manual re-fixturing.

Premium User Experience

· Operator Safety: The fully enclosed cabin design physically isolates the operator from high-speed abrasives, noise, and sparks, adhering to strict industrial safety standards.

· Ease of Operation: The external control interface allows operators to manage the workflow, monitor status, and execute emergency stops without entering the hazardous zone. The automatic loading/unloading interval is optimized to approximately 3 minutes per cycle, reducing downtime.

Sustainable Manufacturing

· Health & Safety: The integrated dust collection system drastically reduces airborne particulates, mitigating health risks for employees and ensuring compliance with environmental regulations.

· Energy Efficiency: With a maximum power consumption of 6.3KW, the system is tuned for high-output grinding while maintaining reasonable energy usage.

Technical Specifications

· Robot Specs: 6 DOF (Degrees of Freedom), 210kg Body Weight, Max Joint Speed 111°/s.

· Material Storage: Max material storage quantity of 10 units (dependent on part size).

· Operating Temp: 0~45°C.

· Drive System: Precision Motor & Reducer.

Cross-Industry Applications

· Automotive: Surface conditioning of wheel hubs, brake discs, and engine components.

· Sanitary Ware: Polishing of faucets, showerheads, and stainless steel sinks to a mirror finish.

· General Hardware: Automated deburring of door handles, locks, and hinges.

Export-Oriented Services

· Modular Logistics: The workstation is designed for modular disassembly to fit standard shipping containers, ensuring safe transport and easy on-site reassembly.

· Compliance: Critical electrical components can be sourced to meet CE or UL standards upon request.

· Remote Commissioning: We provide detailed wiring diagrams and video-assisted setup support to get your workstation running quickly.