Key Attributes Table:

Product Model | Welding Workstation | Robot Radius | 1455 mm |

Positioner Load | 250 KG | Max Power | 6.3 KW |

Repeatability | ±0.06 mm | Frame Size | 1800*800 mm |

Rotation Angle | ±180° | Rotation Speed | 60°/s |

Product Details

Innovative Design Features

· Synchronized Motion Control: The definitive feature of this solution is the coordination between the robot and the single-axis positioner. The positioner rotates the workpiece at 60°/s while the robot welds, ensuring the torch angle remains optimal (flat or fillet position) throughout the process.

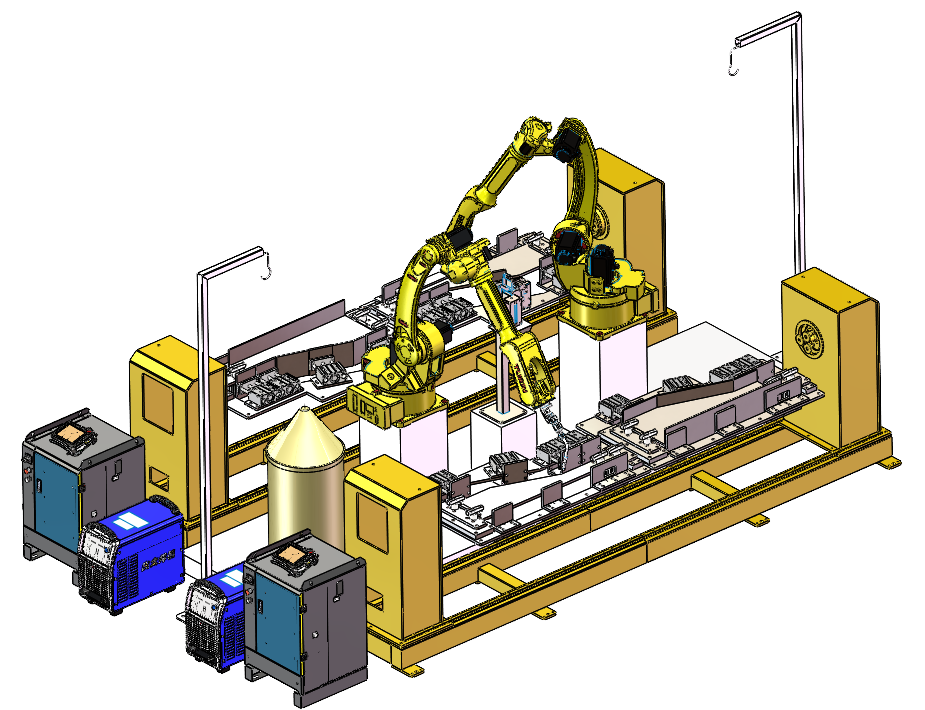

· Flexible Layout Options: The workstation is adaptable to various production flows. It can be configured as a single robot/single positioner cell or expanded into a dual-station layout (as shown in the schematic) to allow for continuous welding while an operator loads the next part.

· Heavy-Duty Stability: The positioner features a reinforced 1800*800mm frame capable of handling loads up to 250kg with an eccentricity of ≤150mm, ensuring vibration-free rotation even for large, unbalanced structures.

Premium User Experience

· Turnkey Integration: This package eliminates the headache of integrating separate components. It includes the robot, power source, wire feeder, positioner, and mounting base as a unified system.

· High-Precision Output: The robot delivers a position repeatability of ±0.06mm. Combined with the positioner's servo control, this ensures uniform weld bead appearance and consistent penetration depth, significantly reducing the need for post-weld grinding.

Sustainable Manufacturing

· Operational Efficiency: The rotating positioner removes the need for manual flipping of heavy parts, replacing the use of overhead cranes and reducing cycle times.

· Resource Conservation: Precise control over welding parameters (Voltage, Current, Speed) minimizes spatter and wire waste, while also reducing shield gas consumption.

Technical Specifications

· Robot Specs: 6 DOF, 160kg Body Weight, Max Joint Speed 149°/s.

· Positioner Specs: Rotation Accuracy ±1mm, Center of Gravity Allowance ≤300mm.

· Drive System: Direct Motor & Reducer Drive for zero backlash.

· Auxiliary Pressure: ≤10 Mpa.

Cross-Industry Applications

· Construction Machinery: Welding of excavator buckets, hydraulic cylinder mounts, and chassis frames.

· Transportation: Fabrication of bicycle frames, motorcycle exhausts, and automotive seat structures.

· Energy Sector: Precision welding of solar panel brackets and battery tray assemblies.

Export-Oriented Services

· Fixture Design: Our engineering team can design and fabricate custom welding jigs based on your CAD drawings to ensure perfect part fit-up on the positioner.

· Weld Process Setup: We pre-configure the welding waveforms (Pulse, Double Pulse) for your specific material (Carbon Steel, Aluminum, Stainless) before shipment.

· Spare Parts Kit: Includes a starter set of consumables (contact tips, nozzles, insulators) to ensure immediate production readiness.